Key AttributesAlcohol-soluble

Excellent resistance to oxidation

Medium softening point

Thermoplastic hydrogenated resin

Very light color

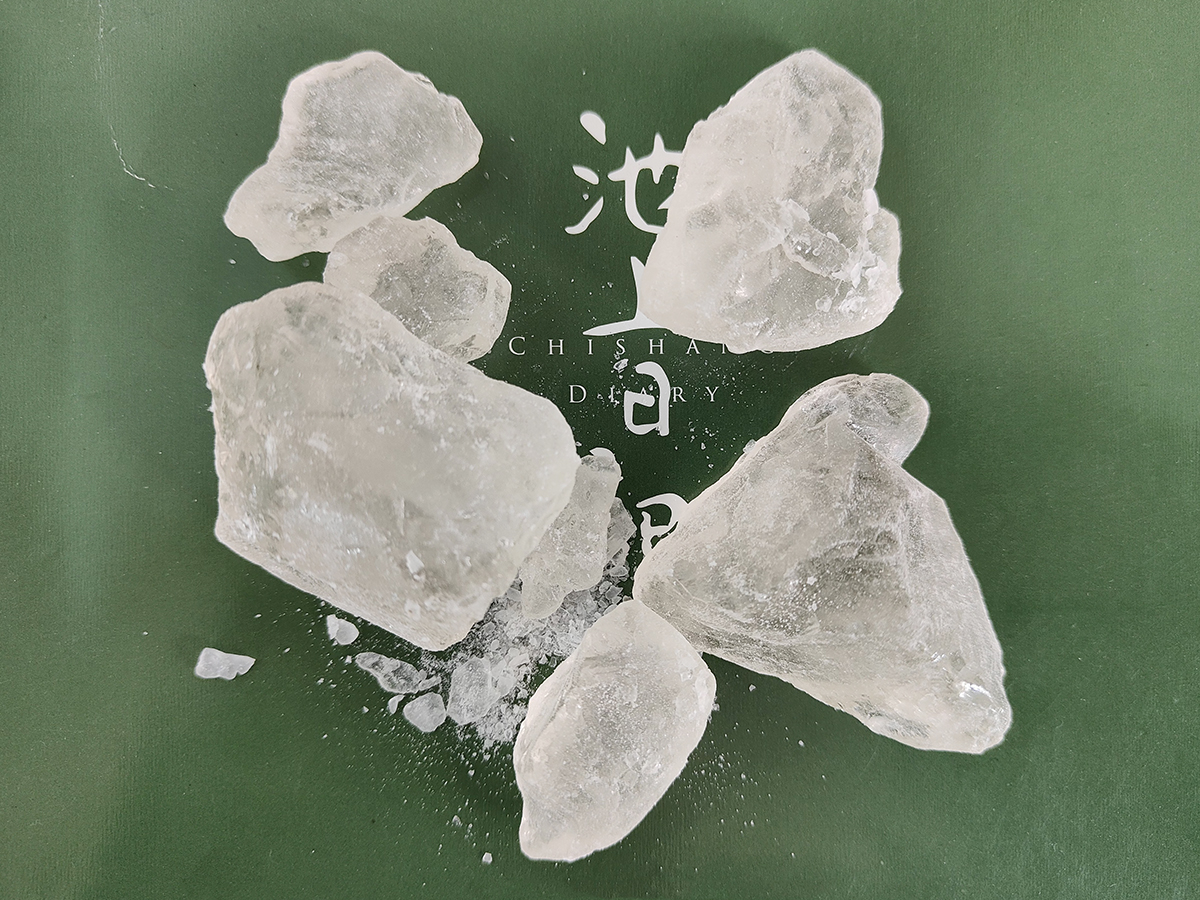

Product DescriptionForal™ AX-E Fully Hydrogenated Rosin is a thermoplastic, acidic resin produced by hydrogenating rosin to an exceptionally high degree. It is the palest, most highly stabilized rosin commercially available. Compared with Staybelite™ Resin-E Partially Hydrogenated Rosin, a hydrogenated rosin long established and widely used for its pale color and high oxidation resistance, Foral™ AX-E Fully Hydrogenated Rosin has better initial color and color retention, and even greater resistance to oxidation. It is especially indicated as the tackifier and resin modifier in solvent adhesives and hot-melt applied coatings and adhesives that must excel in these properties.

Typical Properties

|

Property General |

Typical Value,Units |

|

Softening Point Hercules drop method |

80°C |

|

Color,Hunterlab b |

8 |

|

Color,Hunterlab Ld |

98 |

|

Acid Number (mg KOH/g) |

165 |

|

Refractive Index @100°℃ |

1.4952 |

|

Abietic acid,UV Description,Base Resin |

0.1 % Hydrogenated Gum Rosin |

Compatibility and SolubilityExceptionally pale color, excellent heat stability and color retention, excellent resistance to oxidation. Wide solubility and compatibility, low odor. Compatible at all ratios, or in limited but practically useful proportions, with natural and synthetic waxes, resins, rubber, drying and non-drying alkyds, blow castor oil, ethylcellulose, synthetic elastomers, thermoplastic polymers and copolymers.

Soluble in alcohols, esters, ketones, hydrocarbons, chlorinated solvents, mineral oils. Insoluble in water.

Solubility Parameters, 50% resin concentration. 7,8- 9,5 in Class I solvents - weakly hydrogen-bonded; 7,4-10,6 in Class II solvents - moderately hydrogen-bonded; 9,5-12,7 in Class III solvents - strongly hydrogen-bonded.

PackagingForal™ AX-E Fully Hydrogenated Rosin is pastillated and packed in polyethylene bags of 25 kg net, and supplied on shrink-wrapped pallets of 40 bags (1000 kg) each, from Eastman facilities in The Netherlands and from warehouses located in Europe.

StorageDue to the thermoplastic behavior, pastillated and flaked resins may fuse, block or lump. This can be accelerated under any of the following conditions: 1) above ambient temperature, 2) prolonged storage, 3) pressure, e.g., stacking pallets, or a combination of these conditions. This is particularly applicable for low softening point resin grades.

In order to maintain the flake or pastille shape, we therefore recommend storing the material in a temperature-controlled area, be careful with stacking material or applying pressure and preventing prolonged storage.It should be noted that lumping does not have a negative impact on the product specifications. Due to the nature of the product, claims regarding lumping cannot be accepted.

Resins are prone to gradual oxidation, some more so than others. This could result in darkening and/or it could have an adverse effect on the solubility of the resin in organic solvents or on its compatibility with polymers. Accordingly, it is recommended that strict control of inventory be observed at all times, taking care that the oldest material is used first.Foral™ AX-E Fully Hydrogenated Rosin material will remain within product specification limits, as mentioned under the heading "Product Specifications", for a period of at least twelve months after shipment from Eastman production facilities in The Netherlands, provided storage conditions outlined in this data sheet are observed.

However, as we can neither anticipate the conditions under which the resin is processed nor the end use

applications for which it is used, we recommend that the material be tested upon receipt.

备注:本资料仅提供参考,并不构成本公司承担法律责任的保证陈述。本公司若对相关内容进行调整,恕不另行通知。

-

上一个:KHR-70S高加水白松香

-

下一个:AX-80全氢化松香

深圳新志和

深圳新志和