Typical performance units

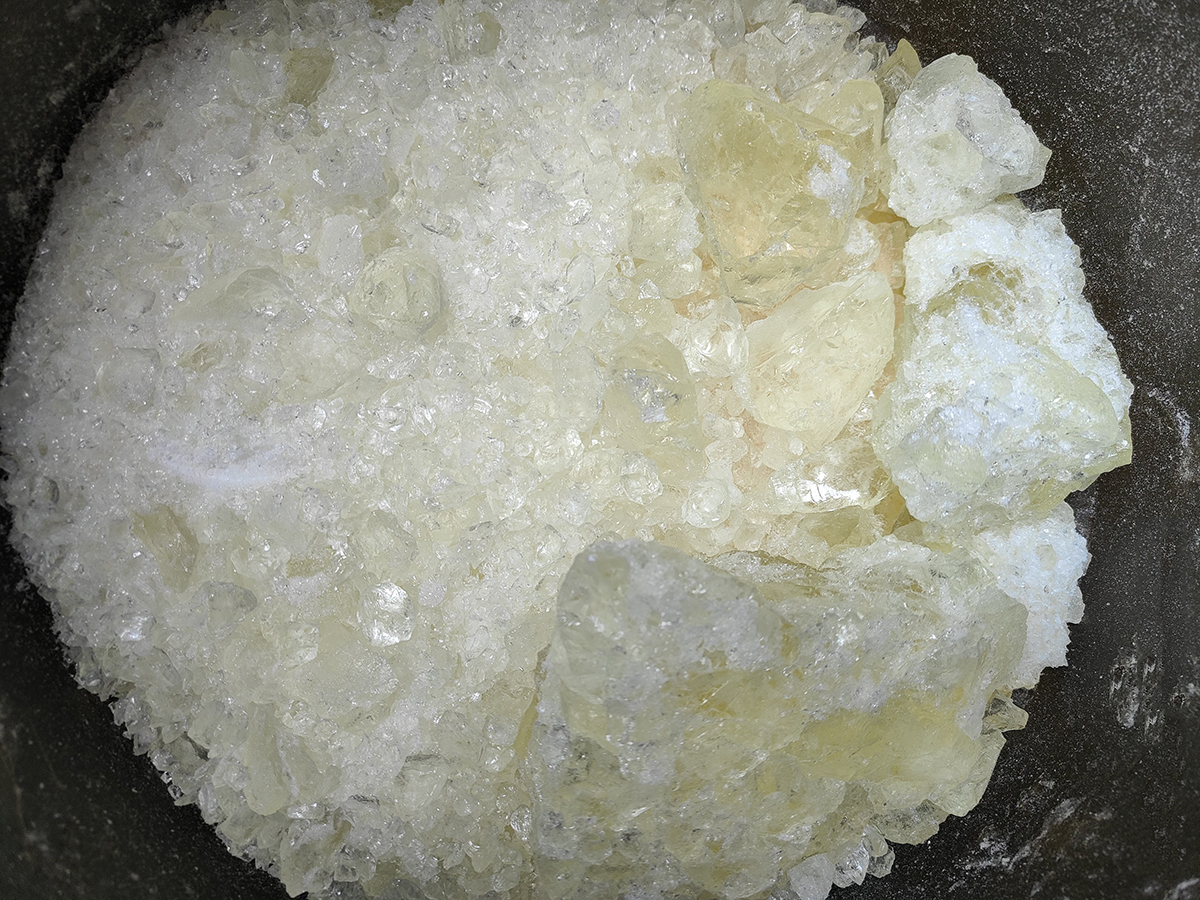

Softening point 75~85°C

Minimum value; color 8

Maximum value; color 98

Acid value 166~180

Compatibility and solubility: extremely light color, good thermal stability and color retention, and high temperature resistance. Antioxidant. Good solubility, good compatibility and low odor. Soluble in alcohols, esters, ketones, hydrocarbons and mineral oil. Insoluble in water.

Packaging specifications: paper bag plus inner plastic or paper barrel, net weight 25 kg, and shrink-wrapped pallet provided, 25 kg per bag/per barrel (1000 kg).

Storage Department: Products that are granular or lumpy, undergo changes under the following conditions: 1) above ambient temperature, 2) prolonged storage, 3) pressure, such as stacking pallets, deformation or color change due to a combination of these conditions. Therefore, it is recommended to strictly control the inventory. Observe at all times and note that the materials that come in first are used first. For use in end-use applications, we recommend that materials be tested for use upon receipt.

Note: This information is for reference only and does not constitute a warranty statement that the company assumes legal liability. The company will make adjustments to relevant content without prior notice.

-

lAST ONE:Special grade rosin

-

NEXT ONE:RHR101 rosin

深圳新志和

深圳新志和