Hydrogenated rosin Introduction: Rosin has excellent properties such as anti-corrosion, insulation, adhesion, and softening, and is widely used in soap, paint, pigment, rubber and other industries. However, there are also some shortcomings, so rosin must be modified, mainly to change the non-cyclic double bond structure in the resin acid, such as hydrogenation (Hydrogenated rosin ), disproportionated ( Disproportionated rosin ), polymerization ( Polymerized rosin ) and other reactions to improve The stability of rosin makes it more widely used and more effective.

The conjugated double bonds of extremely acidic resin undergo hydrogenation reaction intermittently in the presence of a catalyst (activated carbon as a carrier). The hydrogen pressure is 9.SMPa, the temperature is 270°C, the reaction is for 1 to 2 hours, and the catalyst is 0.01%. (For the rosin part), it is saturated with hydrogen and is called Hydrogenated rosin or diHydrogenated rosin , which contains 5% dihydrogen acid. Hydrogenated rosin is widely used in adhesives (glue extenders), such as rubber processing, synthetic rubber, soap (lightfast soap), and is also used in coatings, papermaking, optical instruments, as well as waterproofing agents, preservatives and lubricants.

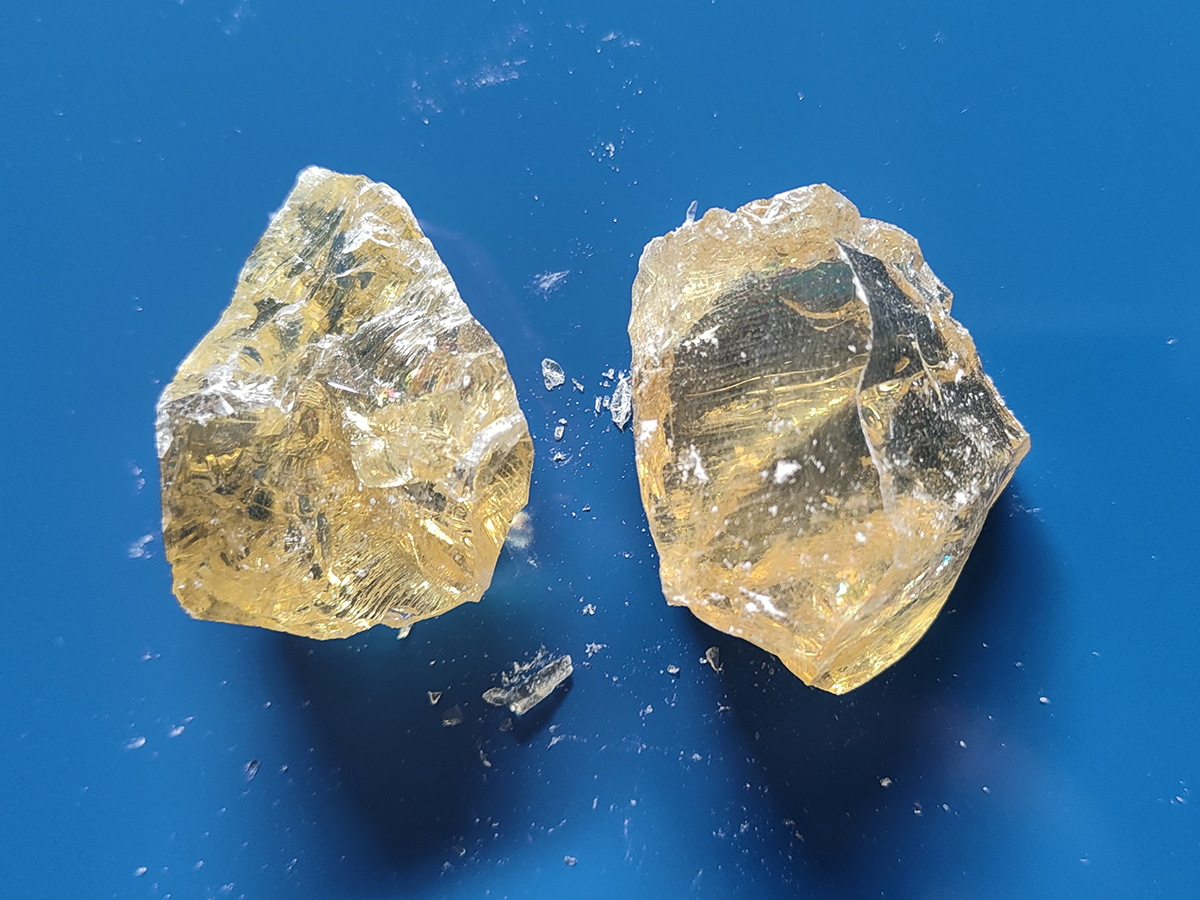

Rosin can be partially or completely saturated with hydrogen. Rosin that is partially saturated with hydrogen is called diHydrogenated rosin , commonly known as Hydrogenated rosin , C19H31COOH, molecular weight 304.46. All saturated with hydrogen is called tetraHydrogenated rosin , also known as PerHydrogenated rosin , with a structural formula of C19H33COOH and a molecular weight of 306.47. The color of Hydrogenated rosin becomes lighter, has high antioxidant properties, does not oxidize in the air, is not easy to change color under the action of light, reduces brittleness, crystallization tendency, increases solubility, improves initial viscosity and compatibility properties, adhesion and aging resistance.

Hydrogenated rosin is an amorphous transparent solid resin containing 75% dihydroabietic acid and a relative density of 1.045. Softening point 70~72℃. Refractive index 1.5270. Viscosity (60% toluene solution) 3.6mPa·S. Acid value 162mgKOH/g. Saponification value: 167mgKOH/g. Flash point (open cup) 203℃. Soluble in ethanol, acetone, dichloroethane, carbon disulfide, toluene, turpentine, petroleum ether, solvent gasoline and vegetable oil. It has good antioxidant properties, low brittleness and high thermal stability. Non-toxic, LD50 7600mg/kg.

Hydrogenated rosin Quality Index

|

Item |

Index |

||||

|

|

Top grade |

First grade |

Second grade |

||

|

Appearance |

transparent |

||||

|

Color |

Glass color block color comparison |

Comply with the requirements of rosin color grade glass standard color blocks |

|||

|

|

No darker than Lovibond |

yellow |

12 |

20 |

30 |

|

|

|

red |

1.4 |

2.1 |

2.5 |

|

Acid value, mgKOH/g ≥ |

162.0 |

160.0 |

158.0 |

||

|

Softening point (ball and ball method), ℃ ≥ |

72.0 |

71.0 |

70.0 |

||

|

Ethanol insoluble matter,% ≤ |

0.020 |

0.030 |

0.040 |

||

|

Unsaponifiable matter,% ≤ |

7.0 |

8.0 |

9.0 |

||

|

Abietic acid,% ≤ |

2.00 |

2.50 |

3.00 |

||

|

Dehydroabietic acid,% ≤ |

10.0 |

10.0 |

15.0 |

||

|

Oxygen absorption°,% ≤ |

0.20 |

0.20 |

0.30 |

||

Uses

Direct application

Hydrogenated rosin can be made into modified rosin for electronics. The flux produced has good soldering performance, high welding reliability, is non-corrosive to electronic components, and is resistant to moisture, heat and mold.

In the adhesive industry, Hydrogenated rosin is often used as a plasticizer in hot-melt, pressure-sensitive, and rubber-type adhesives. For example, Hydrogenated rosin can be used as a thickener for sealing packaging materials.

In the coatings industry, for example, automotive coatings prepared using highly Hydrogenated rosin as raw materials retain their original color and beautiful luster after use; Hydrogenated rosin can also be used as a raw material for solvent-free, environmentally friendly, waterproof paper coatings.

In the food industry, it can be used as a chewing gum base to prevent chewing gum from discoloring during long-term storage; Hydrogenated rosin can also be used to make fruit protective coatings.

In papermaking, Hydrogenated rosin can be used to make high-grade paper with good water resistance and light resistance. In the pharmaceutical industry, Hydrogenated rosin can be used as a thickening agent for ointments.

In the cosmetics industry, Hydrogenated rosin can be used as liquid lipstick; in shampoos, Hydrogenated rosin can increase the luster of hair.

Indirect application

In many cases, Hydrogenated rosin is used in its ester form. In the adhesive industry, it can be widely used as a tackifier in hot melt, solvent and emulsion adhesives. For example, Hydrogenated rosin glyceride, ethylene-vinyl acetate copolymer, microcrystalline wax and other hot melt adhesives have good thermal stability and can be used for bright line binding of books and periodicals, plastic film bonding, furniture manufacturing, shoemaking, and clothing bonding. wait. Hydrogenated rosin glyceride can also be used as a raw material for chlorine-free and wax-free secondary pulping water vapor barrier coatings for flexible packaging materials.

In the food industry, food-grade Hydrogenated rosin ester or rosin glyceride is combined with natural essential oils, emulsifiers, pigments, water and other components to make emulsified flavors through the action of emulsifiers and mechanical force. The soda made from it has a rich aroma, pure taste and a certain turbidity, making the drink more natural in appearance.

In the pharmaceutical industry, food-grade Hydrogenated rosin ester can be made into tablet coatings to act as a sustained-release agent, and can also be formulated with other drugs to form oral ulcer treatment drugs. Hydrogenated rosin esters can also be used to prepare plasters that are absorbed through the skin, and Hydrogenated rosin esters can be used to prepare solvent-free hair removal products containing adhesives and emulsifiers.

In the rubber industry, Hydrogenated rosin soap is an emulsifier for synthetic rubber emulsion polymerization, and can improve certain properties of rubber, such as adhesiveness, processability, etc. For example, Hydrogenated rosin potassium or sodium soap is a good emulsifier for synthetic rubber. Rosin soap can be used as an active filler when left in the rubber, serving as both a plasticizer and a tackifier.

Package

(1). Drum: galvanized iron drum, net weight 225 kg/barrel;

(2).Customer-specified packaging.

Safety measures: Pay attention to fire and heat protection during storage and transportation. Do not store and transport together with self-combustible substances, strong oxidants, and strong acids. Handle according to regulations for flammable substances.

Inventory and inventory control: It is recommended to strictly control inventory at all times and pay attention to first-in, first-out. Pay attention to moisture-proofing. The storage and transportation period is half a year. Please control the inventory. If it is used beyond the storage period, please test it first and then use it.

Note: This information is for reference only and does not constitute a warranty statement that the company assumes legal liability. The company will make adjustments to relevant content without prior notice.

-

lAST ONE:AX-80 PerHydrogenated rosin

深圳新志和

深圳新志和